Welcome to ST Systems

ST Systems is your partner for all aspects of surface treatment systems and special industrial constructions. We accompany our customers' projects from the initial inquiry to the design and commissioning. We accompany every step of the project and advise our customers up to full series production. Our team offers over 50 years of combined experience in surface treatment.

Surface treatment

In the case of surfaces that are difficult to wet (plastics, metals, glass, composites, cardboard, textiles, etc.), treatment of the surface is necessary, in most cases, in order to achieve the optimum surface tension for coating (printing, laminating, gluing, varnishing, etc.). Surface pre-treatment can be carried out under atmospheric pressure using flame, corona or plasma pre-treatment for both inline and offline processes.

In our laboratory we determine, together with our customers, which of the three pre-treatment methods will provide the best possible results for their project and how we can optimally integrate them into their process.

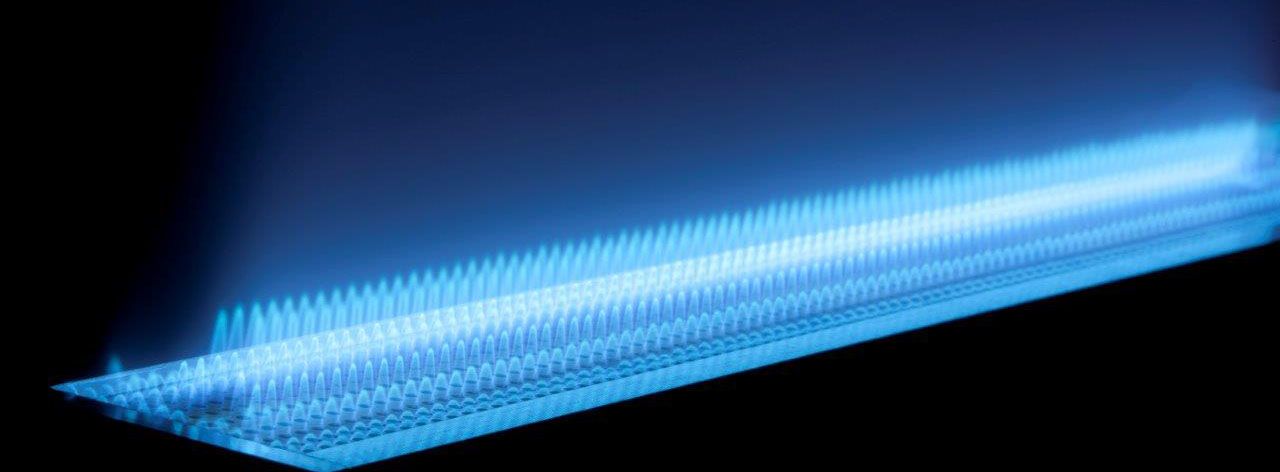

Flame treatment

The ST Systems FU and FUE series flame units are primarily used for inline as well as robotic pre-treatment of injection moulded parts, cups, plastic profiles, syringes, tubes, glass bottles, sheets, cardboard and films, among others.

Optionally all systems of the FU and FUE series can be built 100% CSA, UL and TÜV certified.

The FU and FUE series are suitable for cycle and three-shift operation and can run one or more burners simultaneously. We offer a wide range of burners to meet any pre-treatment requirement. The ST Systems flame units can cover a working width from 25 to 10000mm, at line speeds up to 1600 m/min. All safety-related components of the FU and FUE series are integrated in two channels, in accordance with current safety guidelines.

The FU series measures air and gas flow by means of float flowmeters. The output of the FU series can be adjusted directly at the system by potentiometer or via the integrated industry standard interface via the higher-level plant control system, while maintaining a constant mixing ratio.

The FU series can also be used at manual workstations by using the M-module.

The FUE series measures the air and gas volume by means of mass flow measurement. The output of the FUE series can be adjusted directly at the system or via the integrated industry standard interface or PROFINET/PROFIBUS, via the higher-level system control, while maintaining a constant mixing ratio. All system parameters of the FUE series can be viewed and adjusted directly on the HMI or on the higher-level control system. The standard PLC (also available as safety PLC) allows permanent monitoring of all system parameters and thus offers the optimal solution for plant and process safety.

Corona treatment

The ST Systems corona units of the CU series are primarily used with a corona station for the inline treatment of films, cups, labels, tubes and other materials.

The corona units of the CU series are suitable for cycle and three-shift operation. We offer a wide range of corona stations to meet any treatment requirement. The ST Systems Corona units can cover a working width from 150 to 3000mm, at line speeds up to 800m/min. The integrated industry standard interface enables smooth integration into a higher-level plant control system.

The compact design of the control units of the CU series, as well as the modular structure of the peripheral components, allows almost effortless integration into any machine.

The Corona Unit CUL, which was specially developed for laboratory applications, can be used at manual laboratory workstations by using the L-module. The flexibility of the CUL series allows quick changeover between conductive or non-conductive films and sheets as well as moulded parts. This makes the CUL series an optimal, flexible and resilient partner in everyday laboratory and pre-production work.

Plasma treatment

The ST Systems plasma units of the PU and PUS series are primarily used for in-line treatment of, among other things, injection moulded parts, cups, plastic profiles, adhesive grooves, tubes and folding boxes.

Both machine types are suitable for cycle operation as well as three-shift operation. The integrated industry standard interface enables smooth integration into a higher-level plant control system.

The compact design of the PU and PUS series control units and the modular structure of the peripheral components allow almost effortless integration into any machine.

The PU series with one treatment head can also be used at manual workstations by using the M-module.

The ST Systems PU series plasma units can be operated with up to four treatment heads, each with a working width of up to 85mm, at line speeds of up to 20m/min. The PU series has three head variants to ensure the highest possible flexibility in integration.

The ST Systems PUS series plasma units can be operated with up to eight treatment heads, each with a working width of 8 to 14mm, at line speeds up to 200m/min.

Test inks and test pens

ST Systems test inks are a quick and easy means of determining the wettability (surface tension) of a material surface. The test ink is applied to the surface with a brush or pen. A wettability of at least 38mN/m is a prerequisite for successful printing, foaming and other finishing processes.

To determine the surface tension of a surface, a test ink is used whose surface tension corresponds to the value of the surface to be tested. The behaviour of the applied ink provides information about the properties of the surface. If the ink contracts within three seconds, the surface tension of the surface is lower than that of the ink. In this case, the adhesive forces of the surface material are still too weak. If the ink sticks in the form of a continuous line, the surface energy of the substrate is at least as high as that of the ink.

We would be happy to perform a contact angle measurement for you in our laboratory.

ST-Test Ink, ST-Test Pen and ST-Test Spray are available in blue, pink and green.

ST-Test Inks are available in the setting values 16 to 105mN/m.

Special industrial constructions and automations

If we cannot meet your treatment requirements with one of our systems, we will be happy to work with you to design a suitable special solution for your needs. Furthermore, we offer stand-alone as well as in-line automation solutions for your surface treatment processes.

Maintenance, repair and spare parts

We offer international maintenance, repair and spare parts service for all common treatment systems (flame, corona and plasma). For a large number of spare parts and consumables, delivery within 24 hours is possible.

Contact

Career

For us at ST Systems, work-life balance is not just a buzzword, it is part of our corporate philosophy. We offer our employees a 35 hour, 4 day week on a rotating basis. This means that every second weekend is a long 4-day weekend. If overtime should occur, it is compensated twice; both with time off in lieu and financially.

We are looking for the following employees for our location in Pforzheim:

- Industrial electrician (m/f/d)

- Industrial mechanic (m/f/d)

- Industrial electrician (m/f/d)

Master craftsman or technician

- Industrial mechanic (m/f/d)

Master craftsman or technician

- Mechanical engineer (m/f/d) Design engineer

Catia and AutoCAD knowledge required

- Automation engineer (m/f/d)

PLC programming Siemens TIA Portal and Step 7

- Electrical designer (m/f/d)

EPlan P8 knowledge required

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.